China fully threaded hex bolts wholesale customized

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 3000 TONS

Product name: Hex Head Bolts And Screws With Full Thread

Material: Carbon Steel, Alloy Steel, Stainless Steel

Standard: ASME/ANSI B 18.2.1, IFI149, DIN933, DIN960, DIN961, DIN558, ISO4017, ISO8676, JIS B1180

Measurement system: INCH, Metric

Size: 1/4”-3”, M5-M64

Grade / Class: SAE J429 Gr.2, 5,8; ASTM A307Gr.A, Class 4.8, 5.8, 6.8, 8.8, 10.9, 12.9

Thread: M, UNC, UNF

Finish: Black Oxide, Zinc Plated(Clear/Blue/Yellow/Black), H.D.G. Y.Z.P. Plain, Nickel, Chrome

Hex Head Bolts And Screws With Full Thread

Description

Product name | Hex Head Bolts And Screws With Full Thread |

Place of origin | China(Mainland) |

Brand Name | NEWSTARWDH |

Port | Qingdao or according to requirement |

Delivery time | Normally in 7-35 days, according to quantity |

MOQ | 500kgs for each specification |

Mark | According to customer’s requirement |

OEM | Available |

Fully Threaded Hex Bolt is a type of fastener that's characterized by complete external threading on the shaft — also known as the shank — as well as a pointed tip

The bolt consists of two parts: the bolt and the nut. The full threaded bolt refers to the bolt with the screw part. The 10.9 bolt is the high strength bolt. The chemical industry implementation standard is HG/T20613. The material used is carbon steel. The surface treatment is boiled black hair. The nominal tensile strength of 10.9 bolts can reach 1000MPa, its yield ratio is 0.9, the nominal yield strength of bolts can reach 1000×0.9=900MPa, which is generally used for fastening in machinery industry

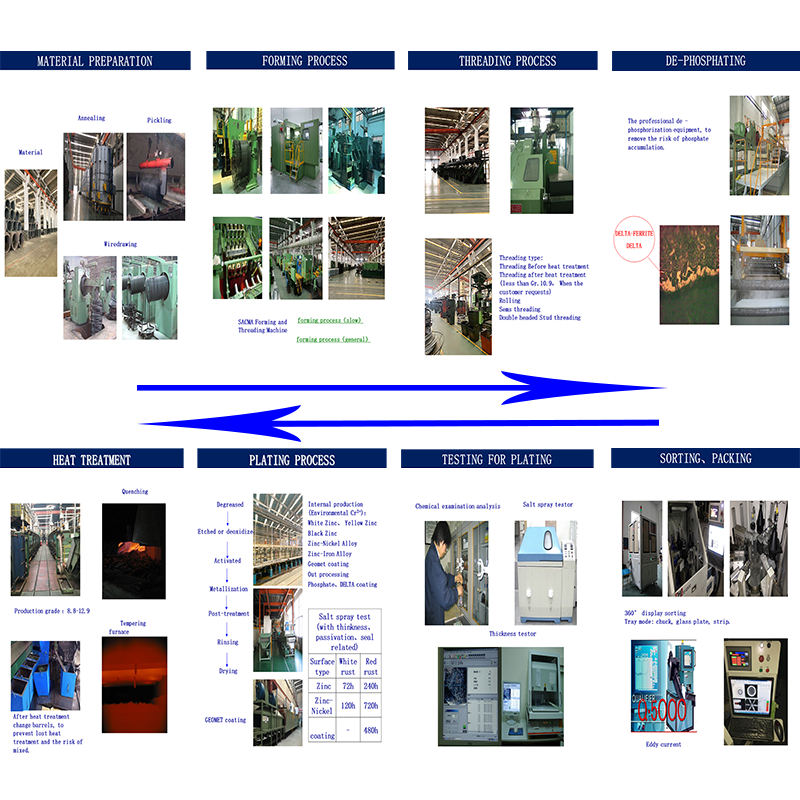

Full threaded bolt production process

Pan → Annealing → Pickling → Draw → Head → Rolling → Heat Treatment → Surface Treatment → Packaging

Product quality assurance

Products are tested by ISO9001:2008 standard products.

Installation and use

10.9 grade bolts are high-strength bolts, which are matched with nuts and flat washers. They are installed with a torque wrench, which is convenient, safe and firm.

Installation and use

10.9-class full-threaded bolts are mated with nuts in use. With the threaded connection, the two parts are connected as a whole and are detachable. The pre-tightening of the connection is to prevent the connection from loosening and strengthen the connection. The bolts mainly carry axial forces during use and sometimes also bear lateral forces. Fully threaded bolts use a spring washer to protect the connected machine when subjected to dynamic loads.

We also accept customization order according to your samples and drawings

If you have other questions or concerns, please feel free to contact us.