Customized bugle head screw wholesale quotes

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 5000 TONS

The self-drilling screw of the horn is a kind of threaded fastener which is self-drilled in the pre-drilled metal or non-metal material. The self-drilling screw of the horn does not require a nut with a female thread, and the female thread is drilled on the material while being screwed in.

Bugle Head Self Drilling Screw

Product Parameters

Standard: | ASME B18.6, DIN7504K, DIN7504P,DIN7504N |

Size: | #4(2.8)-1/2" |

Material: | Carbon Steel, Alloy Steel, Stainless Steel |

Length: | 10-180mm (3/8”- 7”) |

Head type: | bugle |

Drive type: | Phil, slotted, Phil & slotted combination, pozi |

Screw type: | BSD, CSD |

Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G |

Packing: | bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand |

Application: | Structural Steel; Metal Buliding; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating |

Equipments: | Caliper, Go&No-go gauge, Tensile test machine, Hardness tester, Salt spraying tester, H.D.G thickness tester, 3D detector, Projector, Magnetic flaw detecter |

Supply Ability: | 5000 tons per month |

MinimumOrder: | 500kgs for each specification |

Trade Term: | FOB/CIF/CFR/CNF/EXW/DDU/DDP |

Our advantage: | One-stop shopping; OEM |

Notice: | Please lets know the Size, quantity, Material or Grade, surface, If it is special and Non-standard products, please supply the Drawing or Photos or Samples to us |

Description

Product name | Bugle Head Self Drilling Screw |

Place of origin | China(Mainland) |

Brand Name | NEWSTARWDH |

Port | Qingdao or according to requirement |

Delivery time | Normally in 7-35 days, according to quantity |

MOQ | 500kgs for each specification |

Mark | According to customer’s requirement |

OEM | Available |

Four principles for selecting self-drilling screws for the horn

1, choose a professional manufacturer

Professional manufacturers must have the enterprise standard QB of the self-drilling screw head. This standard is reviewed, filed and approved by the State Bureau of Technical Supervision. It involves the current laws and regulations such as the centralization and standardization of the product industry and the mandatory standards of the higher authorities, which is also the guarantee of the production technology of the enterprise. Legislation quite similar to the production technology standards of the company's products

2, Selection of patented products

Almost all horn head self-drilling screws and nuts are patented. The user must see the three basic items recorded on the patent certificate. 1. The name of the patentee. 2. Authorization date and certificate number. 3. The name of the project invented. Prevent some manufacturers and individuals from "hanging sheep to sell dog meat." At the same time, it is necessary to refer to the patent grant date and select the latest recently authorized patent, because it is a newer patent, the higher the technical content.

3, according to the shape and structure

To be "simplified" and not "complex", the simpler the better, at first glance, it is a screw cap, almost no need to read the instructions, you probably know how to use the installation, do not use the complex structure, the bulk weight is too large, the look is strange anti-theft The device, even a set of anti-theft system, can also be used for theft prevention, but the cost of the cost and the complexity of the process cannot be mass-produced, and it is not easy to promote. And it is best to use "tight-type, back-hat type", which can strengthen the fastening nut.

4, safety first

Do not use the self-drilling screw of the horn that is destructive to the bolt structure (strength). It is not possible to install products with unsafe factors. Safety factor first.

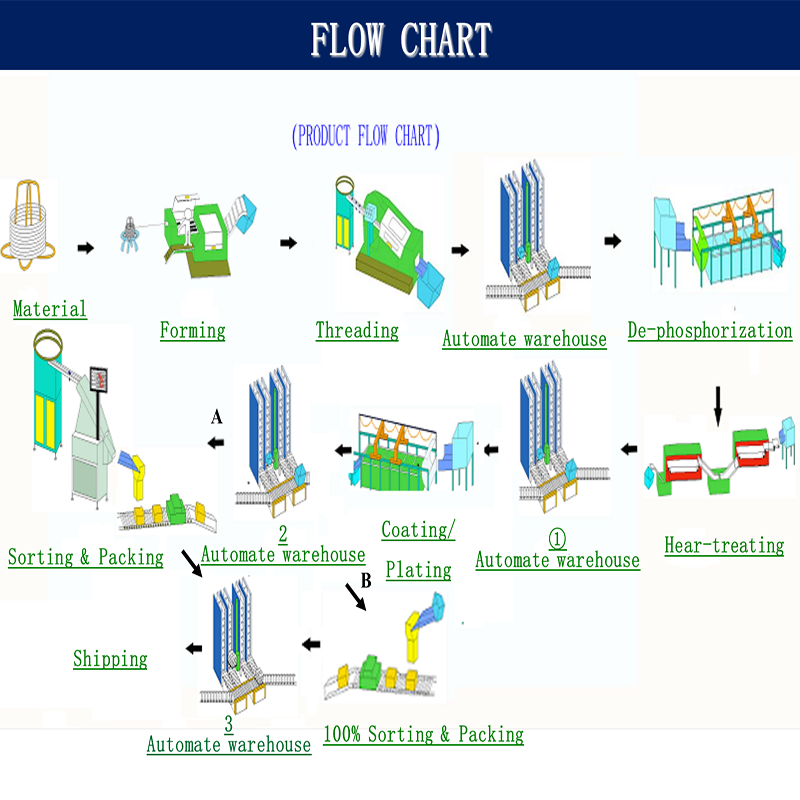

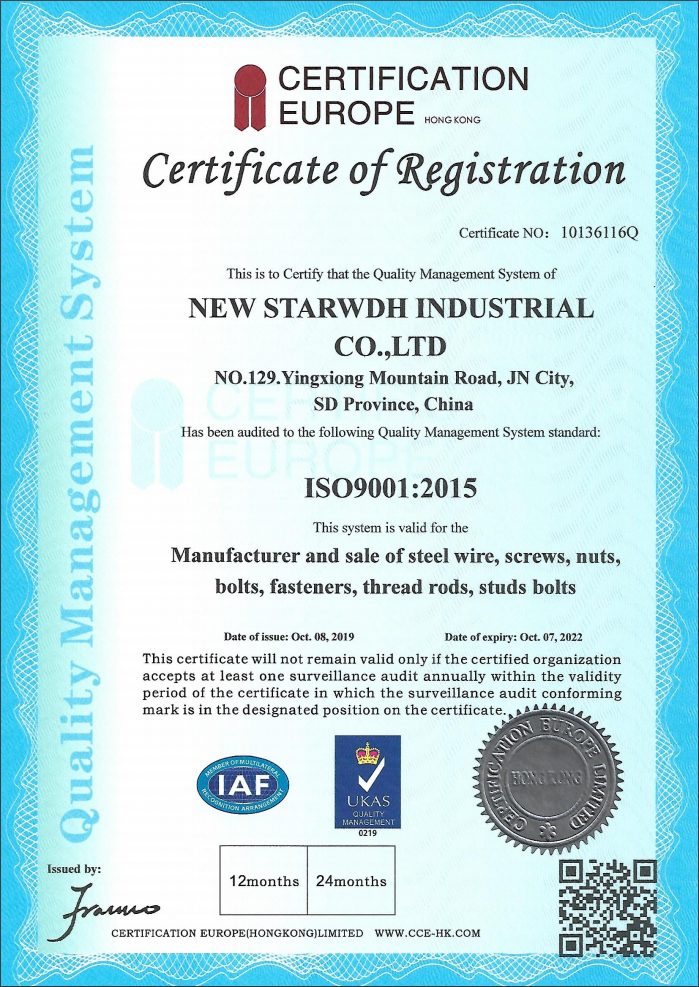

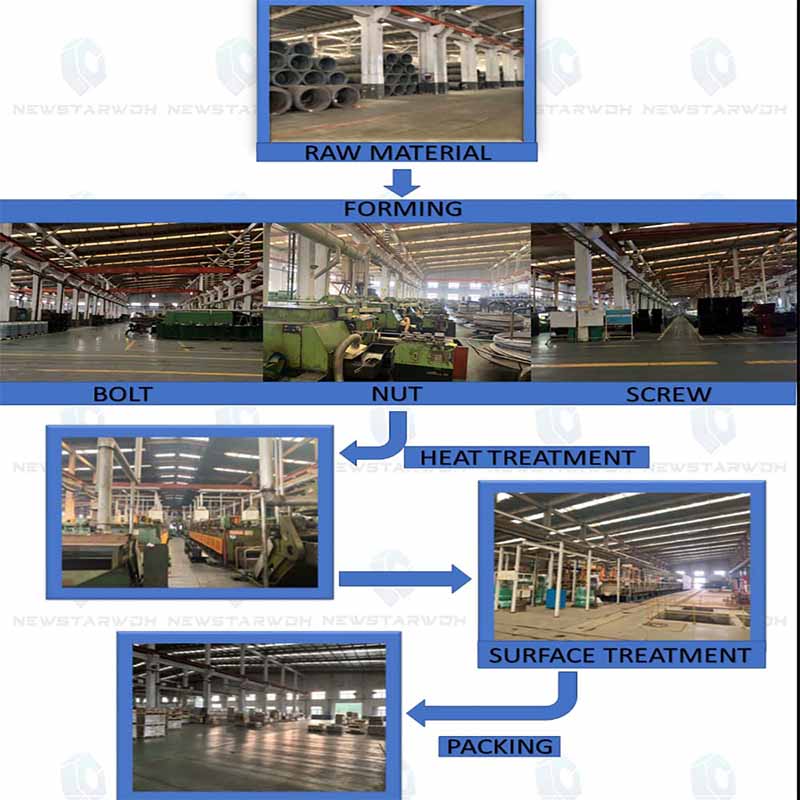

Quality control

our company strictly complies with ISO9001 system. All our products are subjected to strict test and inspection in each process by the workers periodically, starting from the raw materials delivered to the factory.

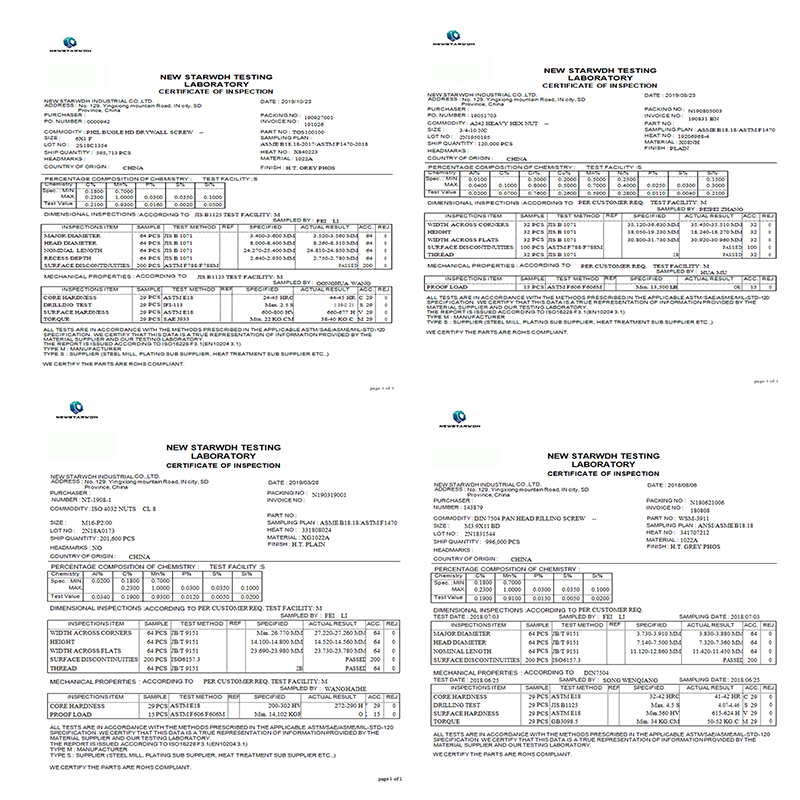

Test Report

If you require, the test report form the third part is available

Packaging Details:

A.

| SIZE | KGS/CTN | KGS/CTN |

| 24CTNS/PALLET | (11-22)KGS/CTN | 0.47 |

| 48CTNS/PALLET | (11-17)KGS/CTN | 0.35 |

| 36CTNS/PALLET | 15KGS/CTN | 0.33 |

| 30,40,50CTNS/PALLET | 15KGS/CTN | 0.35 |

| 36,48CTNS/PALLET | (10-22)KGS/CTN | 0.36 |

| 1CTN/PALLET | 803KGS/CTN | 4.55 |

| BAG | 25KGS/BAG |

B. According to customer special demand.

We also accept customization order according to your samples and drawings

If you have other questions or concerns, please feel free to contact us.