China pan head phillips screw customized quotes

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 5000 TONS

The Phillips pan head screws are specifically designed for use in wood, plasterboard, sheet metal and concrete. It is easier to unload than other fastener screws, a simple special tool can be loosened, and the screws can be reused because they are rarely bent during removal and they can even be inserted into the same hole for use.

Cross Recess Pan Head Screws

Product Parameters

Standard: | ASME/ANSI B18.6 ,JIS B 1111 |

Size: | #5 - 3/4"; M3 – M20 |

Material: | Carbon Steel,Stainless Steel, |

Length: | 10-180mm (3/8”- 7”) |

Head type: | Pan head |

Drive type: | Phillips |

Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G |

Packing: | bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand |

Application: | Structural Steel; Metal Buliding; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating |

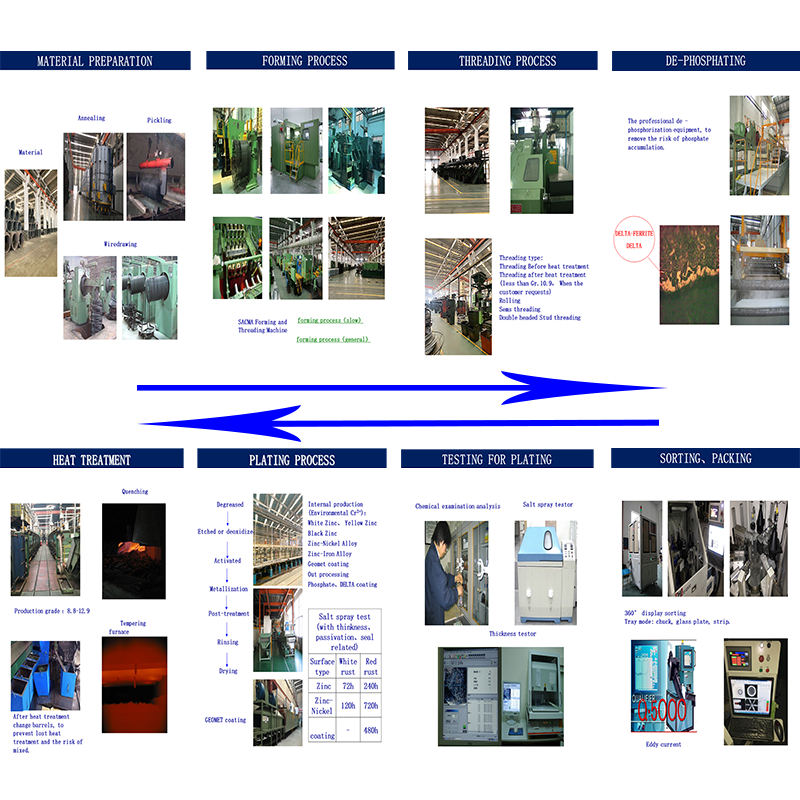

Equipments: | Caliper, Go&No-go gauge, Tensile test machine, Hardness tester, Salt spraying tester, H.D.G thickness tester, 3D detector, Projector, Magnetic flaw detecter |

Supply Ability: | 3000 tons per month |

MinimumOrder: | 500kgs for each specification |

Trade Term: | FOB/CIF/CFR/CNF/EXW/DDU/DDP |

Our advantage: | One-stop shopping; OEM |

Notice: | Please lets know the Size, quantity, Material or Grade, surface, If it is special and Non-standard products, please supply the Drawing or Photos or Samples to us |

Reasons for the slipping of the Phillips pan head screw and improvement method

Manufacturers and users of many Phillips screws often encounter a thorny problem, that is, the electric batch will encounter slippage or severe wear when assembling the Phillips screw.

Many fasteners are now installed with some electric screwdrivers to improve efficiency. When the speed is too fast, or the torque is too large, the cross groove will slip or be severely worn. .

The methods to solve the above problems mainly look at the following aspects:

First, the groove depth of the cross groove of the screw is qualified. Now the cross groove depth gauge (screw depth gauge) has been widely used by the screw manufacturers. If the hole depth is not good, the electric batch head cannot be effectively matched with the screw groove. The force of the grooved wire will be different, causing excessive local wear and slip.

Second, see if the groove shape of the cross groove is qualified. This is generally detected by the cross groove insert. The lifting method can effectively verify the forming condition of the cross groove. If it falls off, the accuracy is not enough, so the degree of cooperation with the batch head is Not enough, the principle is the same as the result of insufficient measurement accuracy of the cross groove depth gauge.

Third, the accuracy of the screw is qualified, can be measured by the thread through the gauge, so as to verify whether the torque of the screw during the screwing process is normal.

Fourth, the hardness measurement of the screw, after the screw has sufficient accuracy, the hardness is more critical. The hardness is generally measured by a micro Vickers hardness tester, which is measured separately from the inner layer. Screws that are not up to standard are very slippery.

Fifth, the torque setting of the electric batch should be reasonable, the electric batch torque measuring instrument can effectively check the torque of the electric screwdriver, and the unit should be tested frequently.